What are lugs or lug joints?

Lug sizing theory is used to design lugs used as connector elements to transfer structural loads with pins. Historically, lugs have been over-designed since weight and size requirements were for the most part, unrestricted. However, the desire for lightweight structures requires the lug joint be designed in an optimized manner that reduces weight while remaining structurally sound. The need for lightweight structures turned previous cross section lug sizing theory into an technique only useful in civil structures.

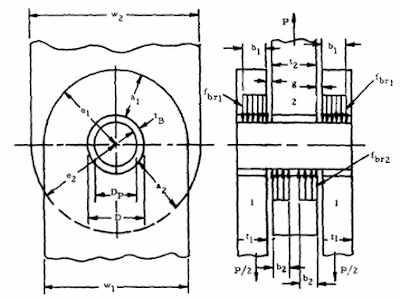

|

| Double Shear Lug Joint |

What lug sizing theories exist?

Numerous lug sizing theories have been devised to calculate lug joint strength. The first methods were simple cross sectional area techniques that resulted in robust, but over-designed lug joints. In the 1950’s, the work of M. A. Melcon, F. M. Hoblit, and F. P. Cozzone from the Lockheed Aircraft Corporation improved upon the original cross section techniques to utilize efficiency factors that permitted more exact lug allowables. The new efficiency factor lug design method produced safe lug joints with reduced weight.

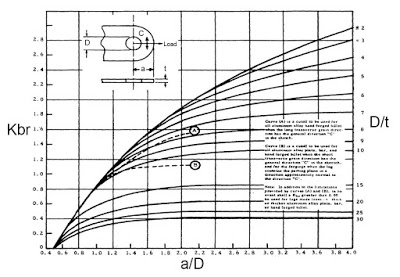

|

| F. P. Cozzone, M. A. Melcon and F. M. Hoblit Original Bearing Efficiency Curves |

Contemporary lug design theory

In 1969, the Air Force Research Laboratory published a hybrid lug design method that did away with material specific lug joint failure tests by relying on more easily obtained material properties, including, ultimate strain, ultimate to yield strength ratio, and two dimensional geometric constants.

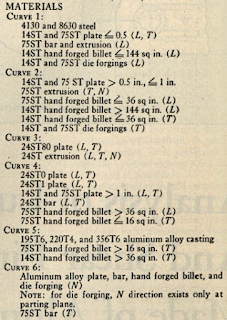

|

| Specially Developed Material Curves for Lug Analysis |

Today, the methods of M. A. Melcon, F. M. Hoblit, and F. P. Cozzone, and the Air Force Research Laboratory method (hybrid) are all widely used.

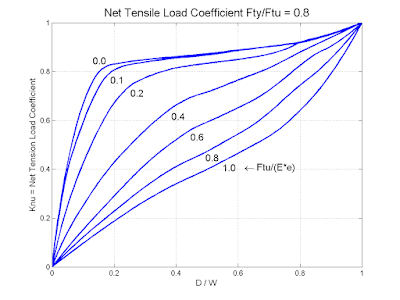

|

| Improved, Non-Material Specific Air Force Research Laboratory Tensile Efficiency Curves |

Hand calculation vs. finite element calculation, which is better?

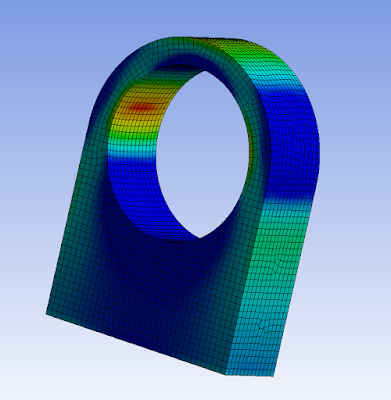

It has been asked if closed form (hand calculations) lug joint design has become obsolete with the advent of finite element techniques. The aerospace industry uses both. Traditional closed form lug theory allow for very fast lug sizing that include some non-linear effects. Running comparable analysis with finite elements techniques is possible but much more costly and time intensive. Today, many aerospace designs are modeled with finite elements but structurally sized and justified with engineering that defaults to the closed form method used by LugCalc.

|

| Finite Element Lug Analysis |

Who should use LugCalc?

LugCalc software is designed for use by those familiar with structural engineering and typical assumptions made in structural design. It is recommended the user be familiar with the content and lug sizing theory detailed in the texts listed on the references page. These references provide step-by-step explanations documenting the analysis process. LugCalc uses the Air Force Research Laboratory method of calculation. All lug calculations assume uniform pin loading. As explained in the reference material, non-uniform loading (pin bending) will contribute to premature lug failure and invalidates any result from LugCalc or the published methods.

Any form of lug analysis and lug sizing theory, including LugCalc, is purely a theoretical estimation. All lug designs require full scale testing to ensure adequacy. This is especially true for safety critical designs.