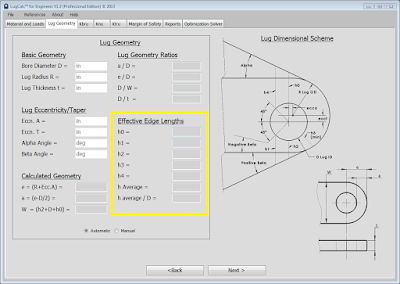

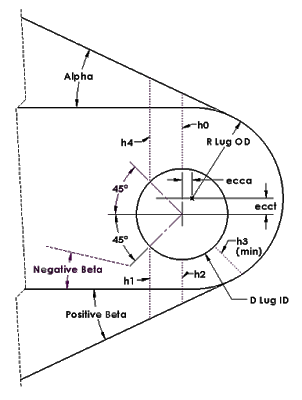

The effective edge lengths are graphically represented in the advanced lug geometry figure. They represent the following:

|

| Effective Edge Length Values |

- h0 and h2: The lengths starting from the centerline of the lug bore edge and ending on the outside of the lug.

- h1 and h4: The lengths originating at a point 45° from bore center beginning at the bore edge and ending on the outside of the lug.

- h3: The minimum wall thickness between the bore inside diameter and the outside radius or side.

|

| Advanced Lug Geometry |

All “h” values are calculated automatically for the user. The method used is variable due to the many variations in geometry with tapered and eccentric lugs. LugCalc provides the exact equations used for “h” length calculation in the reports tool (required for engineering reports).

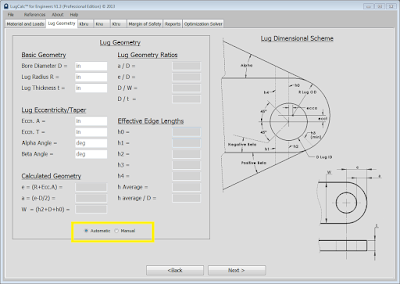

The ability to disable the automatic calculation of “h” lengths is available by clicking the manual geometry radio button. In manual mode, all values for “h” will have to be manually input.

|

| Automatic/Manual Geometry Radio Button |

h average is always calculated as: havg = 6 / ((3/h1)+(1/h2)+(1/h3)+(1/h4))

Note: A proper lug should be designed such that h3 (min wall) is located between h0 and h2. Lug allowable methodologies do not provide techniques to address h3 (min wall) being physically located between h2 and h1 or h0 and h4 (extreme taper and eccentricity). If geometry is input that results in h3 being located between h2 and h1 or h0 and h4, the value for h3 will not be reliable.